Can You Bend Rigid Conduit With a Hand Bender: Find Out

Have you ever found yourself staring at a rigid conduit, wondering if it’s possible to bend it using just a hand bender? You’re not alone.

Navigating the world of electrical conduits can be tricky, especially when you’re trying to figure out the best tools for the job. This question can leave even seasoned DIY enthusiasts scratching their heads. But here’s the good news: you’re about to uncover the secrets of conduit bending, and it might be simpler than you think.

Imagine the satisfaction of shaping that stubborn conduit with ease, saving time and money, and achieving professional-grade results without hiring an expert. You’ll find out whether a hand bender is the right tool for the task and learn some handy tips to make the process smoother. Get ready to transform your electrical projects with newfound confidence. Keep reading to unlock the potential of your hand bender and see if it can truly be your conduit-bending hero.

Credit: www.homedepot.com

Rigid Conduit Basics

Rigid conduit forms a crucial part of electrical systems. It offers protection for wires from physical damage. Made from materials like steel or aluminum, these conduits are tough. They are used where durability is key. Understanding their basics helps in choosing the right conduit.

Types Of Rigid Conduits

Different types of rigid conduits exist for various needs. Steel conduits are strong and resist corrosion. They are ideal for industrial environments. Aluminum conduits are lightweight. They suit residential applications. PVC conduits are non-metallic and flexible. They are perfect for outdoor use. Each type serves a specific purpose.

Common Uses In Electrical Work

Rigid conduits are vital in many electrical projects. They protect wiring in buildings. They are used in underground installations. They prevent damage from water and pests. In factories, they guard against chemical exposure. In homes, they enhance safety and appearance. Their use is widespread due to their reliability.

Hand Bender Essentials

Hand bender essentials provide a foundation for bending rigid conduit effectively. Understanding the tool’s components and operation is crucial for accurate bends. It ensures your conduit fits perfectly into place without compromising the project’s integrity.

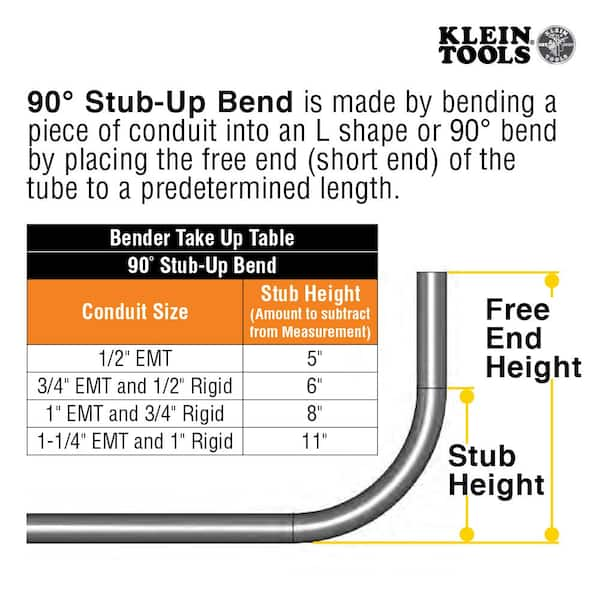

Components Of A Hand Bender

A hand bender consists of several key parts. The handle offers grip and leverage. The bender head, typically made of aluminum or iron, shapes the conduit. There’s also a foot pedal to stabilize the tool during use. The degree indicator guides you in making precise bends. Each part plays a role in achieving accurate results.

How A Hand Bender Works

The hand bender uses leverage to bend the conduit. Place the conduit into the bender head, aligning it with the degree indicator. Apply force using the handle and foot pedal. This action bends the conduit to the desired angle. The process is manual but allows for precise control. It’s essential for maintaining accuracy in your conduit layout.

Bending Rigid Conduit

Bending rigid conduit with a hand bender requires skill and precision. It’s a challenging task, often requiring specific tools and techniques. Mastery of these methods ensures safe and effective conduit installation.

Bending Rigid Conduit Bending rigid conduit can be a challenging task, especially if you’re not familiar with the tools and techniques involved. Rigid conduit is typically used to protect and route electrical wiring in construction projects. Its sturdiness is essential, but this also makes it tricky to bend. Can you use a hand bender for this task? Let’s explore the possibilities and considerations.Feasibility Of Using A Hand Bender

Using a hand bender for rigid conduit is possible, but it requires skill and patience. Hand benders are typically designed for EMT and thinner pipes, making it a bit of a stretch for rigid conduits. You might find the process cumbersome. The effort required could test your arm strength and precision. However, with practice, many electricians have managed to bend rigid conduits using a hand bender. Have you ever thought about how rewarding it would feel to accomplish this?Pros And Cons

Pros: – Cost-Effective: Hand benders are typically cheaper than mechanical benders. This can be a budget-friendly option for small projects or DIY enthusiasts. – Portability: Easy to transport and use on-site. You can carry it around without much hassle. Cons: – Physical Demand: Bending rigid conduit with a hand bender can be physically demanding. Are you ready for the workout? – Precision Challenges: Achieving precise angles may be tough. Mistakes can lead to wasted materials and time. – Time-Consuming: It can take significantly longer compared to using a mechanical bender. Is the balance between cost and effort worth it for you? Consider your project’s scope and your physical readiness before deciding. Bending rigid conduit with a hand bender can be a rewarding challenge if approached correctly. Whether you’re a seasoned pro or a curious beginner, understanding the tools and techniques can make all the difference. Have you got any tips or experiences to share about bending conduit? We’d love to hear them!Step-by-step Bending Process

Yes, bending rigid conduit with a hand bender is possible. Start by marking the conduit where the bend is needed. Carefully align the bender and apply steady pressure to achieve the desired angle.

Bending rigid conduit with a hand bender might seem challenging, but it’s entirely doable with the right approach. Whether you’re a seasoned DIY enthusiast or just starting, understanding the step-by-step bending process can make your project smoother and more successful. Let’s explore the essential steps you need to follow for a precise and effective bend.Preparing Your Conduit

Before you start, make sure your conduit is clean and free of any debris. This ensures a smooth bending process. Measure the length you need to bend and mark it clearly with a marker. A personal tip: Always double-check your measurements. It saves you from repeating the process or wasting material.Executing The Bend

Position your conduit in the bender with the marked point aligned with the arrow on the bender head. Apply steady pressure with your foot on the bender’s foot pedal. As you pull the handle towards you, keep an eye on the angle to avoid over-bending. Here’s a thought: Have you considered practicing on a scrap piece first? It can give you a feel for the tool and improve your confidence.Ensuring Bend Accuracy

Once your bend is complete, lay the conduit on a flat surface to check its accuracy. Use a protractor or angle finder to ensure the bend matches your desired angle. If it’s slightly off, minor adjustments can be made by reapplying pressure with the hand bender. Consider this: How does checking your work early save time and effort? It prevents costly mistakes and ensures your project stays on track. These steps can empower you to bend conduit like a pro. Remember, practice and patience are key. Embrace the learning curve, and soon, you’ll be bending conduit with ease and precision.Safety Tips

Bending rigid conduit with a hand bender requires caution. Ensuring safety while working is crucial. Proper techniques prevent injuries and ensure effective results. Adhering to safety guidelines is essential for a smooth bending process.

Protective Gear

Wear gloves to protect hands from sharp edges. Safety glasses shield eyes from flying debris. Steel-toed boots guard feet against falling objects. Long sleeves prevent scratches from metal surfaces. Ensuring comfort and protection enhances focus.

Handling Precautions

Maintain a firm grip on the bender handle. Ensure the work area is clear of obstacles. Check the conduit for damages before bending. Stand in a stable position to avoid slips. Use the bender properly to prevent injuries.

Alternative Bending Methods

Bending rigid conduit with a hand bender is possible, but it demands skill and precision. Mastery of technique ensures accurate bends without damaging the conduit. This method suits smaller projects where complex machinery isn’t necessary.

When working with rigid conduit, you might wonder if there are alternative methods to bending it without a hand bender. The truth is, while hand benders are common, there are other ways to achieve the bends you need. These methods can save time and effort, especially for those tough angles or when working with larger conduits.Using A Hydraulic Bender

Hydraulic benders offer a powerful solution for bending rigid conduit. They can handle larger sizes and thicker materials with ease. If you’ve ever struggled with a hand bender, you’ll find the hydraulic option a relief. These machines use hydraulic pressure to bend the conduit smoothly. This means less physical strain on you and more consistent results. They’re perfect for projects requiring precision and efficiency. However, hydraulic benders can be more expensive than hand benders. Consider renting one if your project is temporary or if you’re working on a tight budget.Comparing Hand And Machine Bending

Hand benders are great for small, quick jobs. They’re portable and don’t require a power source, making them versatile on any job site. But they require physical strength and skill to produce accurate bends. Machine bending, like with hydraulic benders, offers more precision. It’s faster and reduces the risk of human error. However, it requires initial setup and can be cumbersome for smaller tasks. Think about your project’s needs. Are you tackling a large-scale project or just a small home repair? Your answer can guide you to the right bending method. Have you ever used a machine bender and found it surprisingly easy? Or did you miss the simplicity of a hand bender? Your experience can shape the tools you choose in the future.Troubleshooting Common Issues

Bending rigid conduit with a hand bender can be challenging. Hand benders are typically designed for flexible conduit. Using a hand bender on rigid conduit often leads to poor results or damage.

Troubleshooting common issues while bending rigid conduit with a hand bender is crucial. Mistakes happen even with experienced electricians. Understanding how to avoid and correct these issues can save time and materials. It ensures a smooth and efficient process. Here, we focus on avoiding conduit damage and correcting common bending mistakes.Avoiding Conduit Damage

Bending rigid conduit can be tricky. Excessive force can crack or deform the conduit. Always check the bender’s shoe size. It should match the conduit diameter. Incorrect sizes can cause damage. Keep the conduit clean and free of debris. This helps prevent unwanted scratches or dents. Apply steady pressure during bends. Jerky movements can lead to uneven bends.Correcting Mistakes

Mistakes are not uncommon. A slight overbend can be corrected. Use the bender to carefully reverse the bend. Go slow to avoid further damage. Underbends require additional bending. Place the conduit back into the bender. Apply gentle pressure until the desired angle is achieved. If the conduit is kinked, it might need replacing. Always assess the damage before deciding.

Credit: www.youtube.com

Credit: ipvm.com

Frequently Asked Questions

Can You Bend Rigid Conduit Manually?

Yes, you can bend rigid conduit manually using a hand bender. However, it requires proper technique and strength. Rigid conduit is less flexible than other types, making it challenging. Ensure you use the correct size hand bender for the conduit.

Practice and patience are key to achieving the desired bend.

What Tools Do You Need To Bend Rigid Conduit?

To bend rigid conduit, you need a hand bender designed for rigid types. Ensure the bender matches the conduit size. Additionally, a tape measure, level, and marker help ensure accuracy. Proper safety gear, like gloves, is also recommended to prevent injuries during the bending process.

Is Bending Rigid Conduit Difficult?

Bending rigid conduit can be challenging due to its stiffness. It requires strength and precision. Using a hand bender makes it manageable, but practice is essential. Understanding the proper technique is crucial for achieving accurate bends. With experience, the process becomes easier and more efficient.

What Are Common Mistakes When Bending Conduit?

Common mistakes include using the wrong size bender, incorrect measurements, and improper technique. These can lead to inaccurate bends or damaged conduit. Always ensure measurements are precise and use the appropriate bender. Practicing the correct method can help avoid these mistakes and result in successful bends.

Conclusion

Bending rigid conduit with a hand bender is possible. But it takes practice. Follow the steps carefully. Use the right tools for the job. Measure and mark accurately. Apply steady pressure. Check your work frequently. Mistakes can happen, but learn from them.

Safety first, always. Wear protective gear to avoid injuries. Understand the basics, and improve with time. With patience, your skills will grow. Soon, bending conduit will feel natural. Keep practicing to gain confidence. Remember, every expert was once a beginner.

Good luck with your projects!